If e.g. the maintenance staff discovers that a certain type of points tend to have loose bolts then there have to be an office, guard, database or other report system where the incident can be reported.

There also have to be somebody in the organization that reads this report and takes appropriate corrective action.

Potters Bar accident in UK, 2002, due to loose bolts in a point

Interpretation

It sounds easy; but investigation reports from accidents and “near miss” incidents often shows that the implemented FRACAS did not work properly: The points were poorly maintained, the failure report was shelved, the engineers misjudged data, the supplier never fixed it, the appropriate procedure was not updated or the purchasers lacked time to buy new bolts.

Regularly audits are a suitable tool for examining the implemented FRACAS system.

Statistics is a helpful tool, because it removes emotions from a problem and forces the safety management to take action.

Next chapter >> 4.3 Using the ALARP principle

Focus on the Source

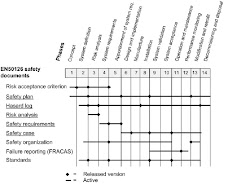

Chapter 6.12 , “Phase 12: Performance monitoring” in EN 50126:1999 describes the objectives and requirements to this phase:

6.12.3 Requirements

6.12.3.1 Requirement 1 of this phase shall be to establish, implement and regularly review a process for:

- the collection of operational performance and RAMS statistics;

-the acquisition, analysis and evaluation of performance and RAMS data; checking that the assumptions made in the safety case remain valid.

6.12.3.2 Requirement 2 of this phase shall be to analyse performance and RAMS data and statistics to influence:

- new operating and maintenance procedures;

- changes in logistic support for the system.

Ingen kommentarer:

Send en kommentar